How Ultrasonic Flow Water Meter Work?

Water Conservation App | Optimizing Water Consumption with Residents’ Mobile App

2024-04-19

Ultrasonic Meters vs Mechanical Meters: The Advantages and Disadvantages

2024-05-16Ultrasonic water meters are transforming how we measure fluid velocity, using sound waves instead of moving parts to deliver highly accurate and reliable readings. These meters fall into two main categories: transit-time and Doppler, each designed for different applications.

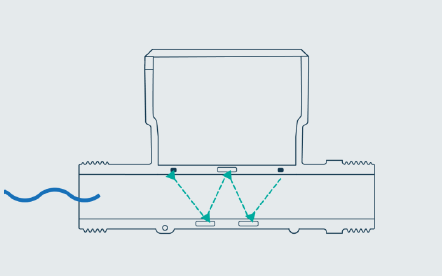

Here’s how they work: ultrasonic flow meters transmit sound waves through a pipe. In the transit-time method, the meter compares how long it takes for sound waves to travel between transducers with and against the direction of flow — the difference reveals the flow rate. In the Doppler method, the ultrasonic signal reflects off particles or air bubbles in the liquid, and the resulting frequency shift is used to calculate flow.

From residential and multifamily buildings to utility networks, ultrasonic meters provide precise, maintenance-free measurement. They also come in several configurations — inline, open channel, and clamp-on — making them adaptable to a wide range of systems.

Ultrasonic Flow Meter Working Principle

Ultrasonic flow meters operate by sending ultrasonic waves through the fluid medium. Two methods for measuring flow using ultrasonic technology are the Doppler Method and the Transit-Time Method. Although both use ultrasonic technology, each works slightly differently.

Let’s take a look at the core components of an ultrasonic flow meter to better understand how they work. Broadly speaking, ultrasonic flow meters possess these key components essential to their functioning:

- Ultrasonic transducers: These generate and receive ultrasounds.

- Coupling/mounting system: These ensure that ultrasounds enter the fluids.

- Drive electronics/pulser: These excite transducers, allowing them to emit ultrasonic bursts or waves.

- Receiver: Receivers amplify and condition received signals.

- Time-measurement or frequency-analysis unit: These are essential for measuring the time taken for wave travel in transit-time meters or to extract the frequency shift in Doppler meters.

- Digital signal processor/microcontroller: These do the calculations necessary for the meter’s function.

- Optional auxiliary sensors: These include temperature/pressure/density sensors.

- Power supply: Necessary for the meter to function at all.

- Communications interface: Smart meters generally include a wireless communications technology like LoRaWAN or WM-Bus, but wired methods also exist.

- A display: The display allows end users to see the calculated flow.

Next, let’s consider how each type of ultrasonic flow meter actually works.

In the transit-time method, an ultrasonic wave is pulsed through the fluid. The time it takes for these waves to travel upstream and downstream is measured. By analyzing the difference in transit times between these pulses, the flow meter can calculate the velocity of the fluid. Because this time difference is proportional to the average fluid velocity along the acoustic path, it’s possible to calculate the flow.

This velocity measurement, combined with the cross-sectional area of the pipe, enables the flow meter to determine the volume flow rate of the liquid passing through the pipe. The ultrasonic waves are typically generated by transducers located inside the ultrasonic water meter, which emit and receive the ultrasonic signals. These signals are angled across the flow path to ensure accurate readings.

In brief, here are the steps taken by a transit-time ultrasonic flow meter when it measures flow:

- An ultrasonic pulse is generated and sent through the pipe by the transducer.

- Downstream transit time is measured.

- The roles of transducers are reversed, and a pulse is sent through the pipe in the opposite direction.

- The upstream transit time is then measured.

- The time difference is computed.

- The velocity is calculated.

- The velocity is converted to the flow rate.

- Pressure/temperature sensors are used to account for sound speed changes.

Transit-time ultrasonic flow meter measurements generally work best on smooth, clean fluids like oil or water, as bubbles or heavy particulates can disrupt accuracy.

This is because factors such as temperature, density, viscosity, and the presence of suspended particles can influence the speed of sound in the fluid, impacting the accuracy of the flow measurements. However, advancements in ultrasonic flow meter technology have led to improved accuracy and reliability even in challenging operating conditions.

In Doppler ultrasonic flow meters, the frequency shift of echoes reflected from moving scatterers in the fluid is measured. Rather than measuring the speed of a sound wave as it moves through the pipe, Doppler meters send an ultrasound into the fluid and measure its change in frequency as it bounces off particles, bubbles, and turbulent eddies. The measured frequency shift, called the Doppler shift, is proportional to the particle velocity along the beam. Since the Doppler shift is proportional to the velocity it can be used to calculate velocity and therefore, flow rate through the pipe.

Here’s how a Doppler ultrasonic flow meter works in simple steps:

- Transmit ultrasound.

- It bounces off particles/bubbles.

- The echoes are received.

- The frequency shift is measured.

- Velocity is calculated.

- Flow rate is derived.

- Output is stabilized.

Unlike with transit-time measurements, Doppler ultrasonic flow meters are well-suited to dirtier water and fluids – slurries, aerated liquids, wastewater, or some medical applications. So depending on the ultrasonic flow meter, applications can vary, but ultrasonic flow measurement is a precise, accurate, and reliable way to measure fluid flow when used correctly.

Features and Benefits

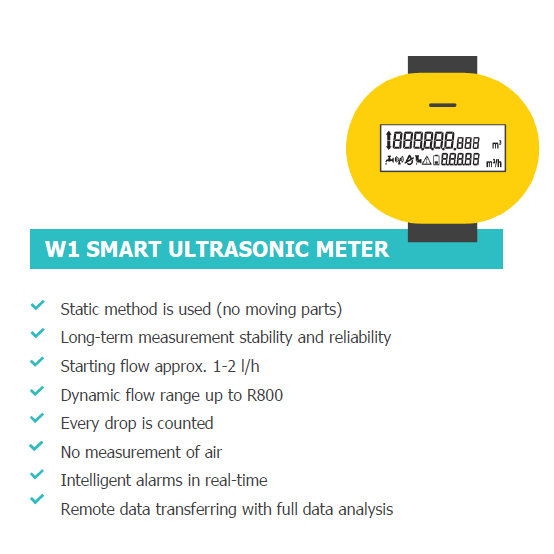

Ultrasonic flow meters are a genuinely innovative device with several vital qualities. High accuracy, large measuring ranges, and low starting flows (as low as 0.26 gallons/hour) are just a few of them. Ultrasonic flow meters are long-lasting and dependable because they don’t have any moving components like conventional mechanical meters. They are crucial for tiered billing and water resource management due to their ability to resolve conventional water meter issues.

Ultrasonic flow meters satisfy the needs of contemporary communication networks like LoRaWAN. Therefore, extensive output communication capabilities open the door for their wider adoption and application.On the left-hand side you can see some of the benefits of Axioma W1 Ultrasonic Water Meter.

Ultrasonic Flow Meter Applications

Ultrasonic flow meters are commonly used throughout a range of industries and contexts, including oil and gas, construction and manufacturing, commercial premises, HVAC and Building Management, and residential and municipal contexts. Our ultrasonic water flow meters are used in single-family residential homes, commercial premises, multi-family spaces like apartment buildings or mobile home parks for submetering, and city, district, and municipal contexts.

In any property where accurate unit-by-unit data is required, ultrasonic water meters provide the necessary visibility and control. They support submetering in compliance with regulations (such as in California), enable leak and non-revenue water detection, generate alerts, give residents insight into their own water use, and allow for remote, automated meter readings. That is where ultrasonic water meters come in.In our recent case study we reveal how Húsafell in Iceland, Mainlink and Axioma Metering’s solution was able to cut water use by 30%, save a significant amount of water resources, reduce resident complaints drastically, and show that even the most sustainable communities benefit from advanced ultrasonic meters.

Ultrasonic Flow Meters vs. Ultrasonic Water Meter

Although the working mechanism of both types of meters is the same, ultrasonic flow meters have broader potential uses. They can measure a wide range of fluids, while ultrasonic water meters are designed especially for water. These include alcohol, chemical liquids, petroleum, and water. Despite this distinction, ultrasonic technology is used by both to provide accurate and dependable flow readings, promoting sustainability and efficiency across industries.

Ultrasonic water meters operate using the transit-time method. This method is perfect for clean water, such as in potable water billing, residential or municipal metering, or similar contexts. However, it’s not particularly well suited for extremely dirty water with a lot of particles or turbulent eddies. Its high accuracy in clean water makes it exceptionally useful in municipal, commercial, and residential water metering.

Ultrasonic flow meters may use either principle, but many industrial models use Doppler because it’s better suited to fluids with heavy particulates. This makes ultrasonic flow meters an excellent choice in wastewater processing or for many industrial processes, where this additional versatility can be essential for smooth operations. Doppler’s efficacy in these kinds of fluids is a direct result of the particles or bubbles inside them, so it’s not as accurate or effective in clean water.

How Does Ultrasonic Flow Water Meter Installation Work?

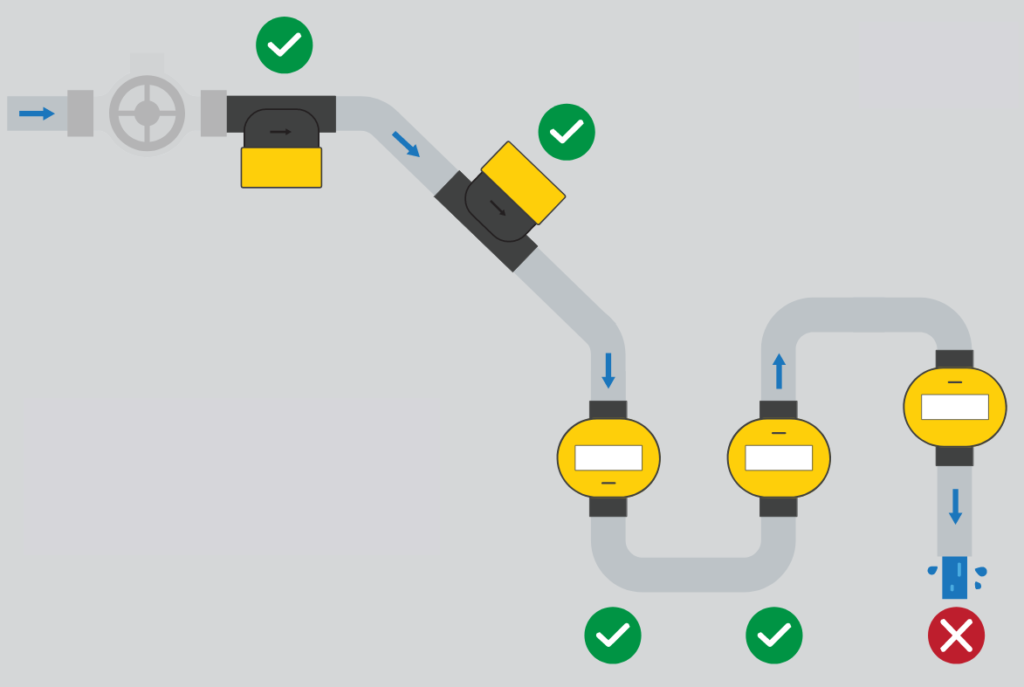

It might surprise you, but you can mount ultrasonic water meters in any way. Unlike traditional mechanical water meters, which may have specific orientation requirements due to the mechanics involved, ultrasonic flow meters are much more flexible.

Whether installed horizontally or vertically, ultrasonic meters deliver accurate and reliable measurements. The key factor to consider is the alignment of the meter’s sensor with the direction of water flow. This alignment ensures optimal performance and precise measurement accuracy. Whether mounted horizontally along a wall or vertically within a piping system, ultrasonic water meters adapt seamlessly.

This flexibility in orientation is a testament to the advanced technology and engineering behind ultrasonic water meters. It offers greater convenience and versatility for installers, allowing them to accommodate different plumbing configurations with ease. This innovative flexibility allows ultrasonic water meters to meet diverse water management needs in residential, commercial, and industrial settings.

Where is the best place to put an ultrasonic water meter?

Determining the optimal placement for an ultrasonic water meter involves several considerations to ensure accurate measurement and efficient operation. The ideal location for installing an ultrasonic water meter depends on a few factors:

One of the primary considerations when determining the best placement for an ultrasonic water meter is accessibility. The meter should be easy to access for maintenance and servicing. Opt for a location that allows for quick and convenient inspections, as well as any necessary repairs. This minimizes disruptions and downtime, keeping your water meter running smoothly.

Another Key factor is Network and Connectivity. Consider the communication networks used by the smart water meter to transmit readings and alerts. Ensure that you place the meter in an area where it can easily connect to these networks. For example, if you enclose it in a thick metal box, it may struggle to communicate wirelessly with LoRaWAN, NB-IoT, or cellular.

Flow Dynamics: Take into account how water flows through the pipes in your plumbing system. Choose a location where the flow is consistent and around 0.3 bar to ensure accurate measurement. If you’re planning to use a W1 ultrasonic water meter, ensure that you align water pipes on the same axis. Misalignment of the axles of the pipes poses a huge risk of lateral stress and breaking the meter. Either instantly or afterward. In a case where aligning the axles of the pipes is not easily available, a simple recommendation is to use flexible pipe connectors.

Consider the environmental factors that may impact the meter’s operation. Ensure that the chosen location protects the meter from extreme temperatures and potential damage from external elements. This helps preserve the integrity of the meter and maintains accurate readings over time. It’s worth noting that W1 ultrasonic water meters boast waterproof capabilities, boasting an IP68 rating. This designation ensures that the meter is resilient against water ingress, enabling you to safely place it in flood-prone areas like outdoor environments or pits.

Conclusion

To sum up, ultrasonic flow water meters, which provide accuracy and dependability, constitute a substantial breakthrough in fluid velocity measuring. Their flexible designs and variations in Doppler and transit-time methods allow them to serve a wide range of applications — because Doppler works by bouncing sound waves off particulates and other materials, it is well-suited to dealing with dirtier water or other use cases where transit-time, which requires clear fluid, is unsuitable.

Their versatility in installation, cutting-edge technology, and robustness make them invaluable in a range of environments. While ultrasonic water meters focus on potable water measurement, ultrasonic flow meters extend the same principle to a wide variety of industrial fluids.

When positioning an ultrasonic water meter, take accessibility, network connectivity, flow dynamics, and ambient variables into account for best results. You can guarantee precise measurements and successful water management in residential, commercial, and industrial settings by making proper use of their capabilities.

If you’re looking for a reliable and cost-effective ultrasonic water meter consider our Flagman full-solution water submetering offer. If you need any help with water submetering, or you have questions about LoRaWAN network use cases for submetering, contact us and we will do our best to help you.

If you’re looking for a reliable and cost-effective ultrasonic water meter consider our Flagman full-solution water submetering offer. If you need any help with water submetering, or you have questions about LoRAWAN network use cases for submetering, contact us and we will do our best to help you.